Services

Survey ManagementSurvey Management

![]() ™

™

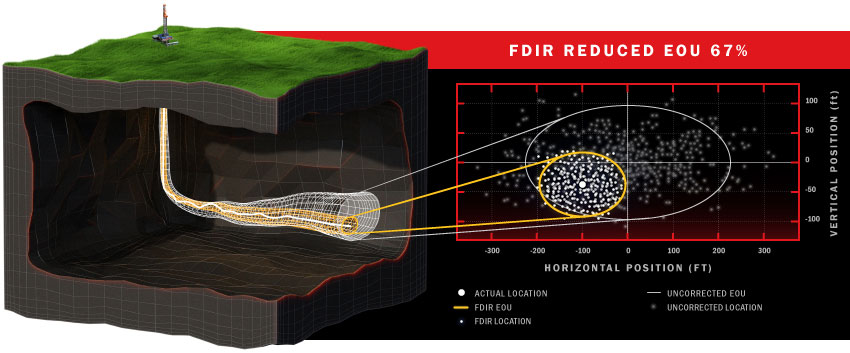

FDIR™ (Fault Detection, Isolation, and Recovery) is Superior QC’s industry-leading automated survey correction technology. Unlike traditional MSA (Multi-station Analysis) corrections that are dependent on human interpretation and can only correct for up to 6 sources of measurement error, FDIR™ leverages machine learning algorithms and artificial intelligence to provide a single solution correction that accounts for all 27 sources of measurement error.

Precision Well Placement

Innovative adaptation of aerospace GNC (Guidance, Navigation and Control) logic applied to survey measurement data allows FDIR™ to produce comprehensive survey corrections. The result is the most statistically accurate interpretation of wellbore position available with magnetic MWD surveys.

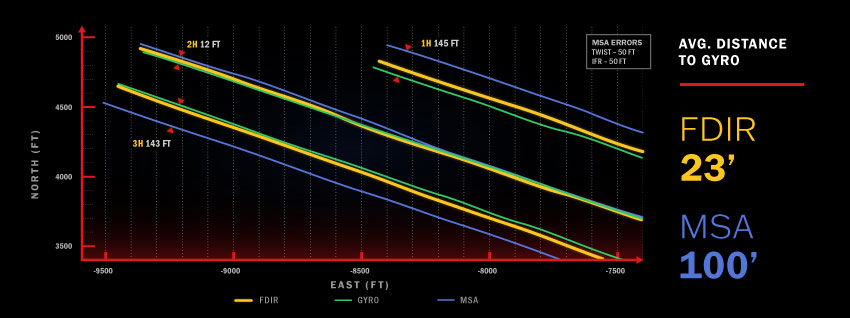

Accuracy Comparison Against Gyros: FDIR™ vs MSA

The superior wellbore placement accuracy of FDIR™ over traditional MSA corrections has been demonstrated and validated by multiple case studies comparing both survey correction methods to gyroscopic (gyro) surveys of the same well. Relative to gyro surveys, the average well spacing error for MSA corrected surveys was greater than 4 times that of the FDIR™ corrected surveys.

> Case Study

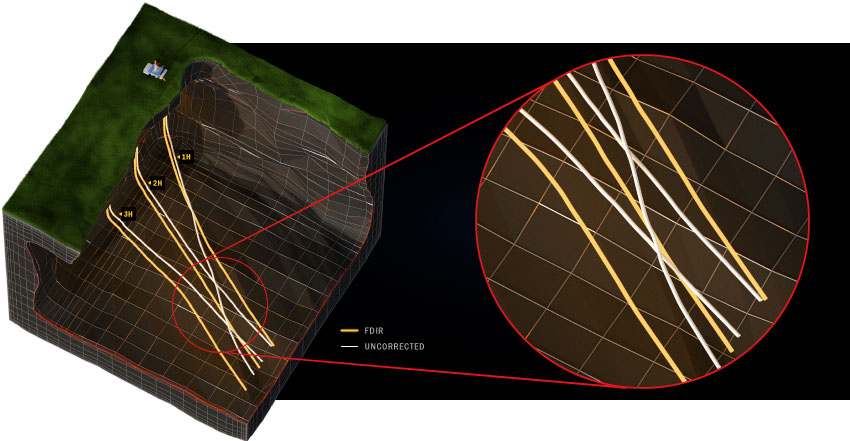

Completions & Production

Accurate placement & proper well spacing will result in the reduction of cross well communication/frac hits while maximizing hydrocarbon recovery.

> Case Study

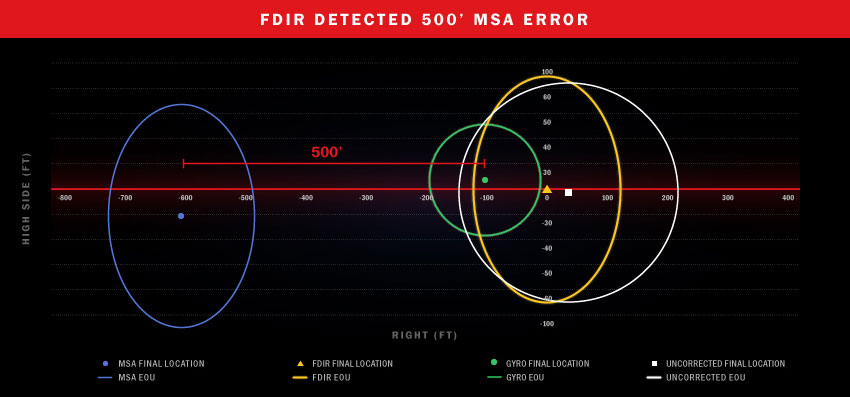

Expand East/West Drilling Opportunities

Traditional MSA corrections are subject to a restrictive East/West exclusion zone, resulting in increased risk of large well placement errors if utilized near the East or West cardinal directions. FDIR™ is not vulnerable to these errors due to the comprehensive nature of its correction, granting the operator the ability to drill the well in any direction with confidence.

> Case Study

Automated Safeguards

To ensure accuracy and reliability, FDIR™ performs over 100 automated error checks that include identifying potential mistakes in: input data, reference fields, geographic data, and many others.

> Case Study

$300K saved

Example: FDIR™’s automated safeguards identified a magnetic declination input error of 1.92 degrees that was overlooked by the well planner, MWD engineer, and directional driller. Had this error not been identified and corrected, the well would have been drilled 300’ across a lease line resulting in a costly production fine for the operator.